WHAT ARE THE BENEFITS OF FRONT PANEL LIGHT GUIDES?

- Quick Links

- Graphical Range Overview of Front Panel Light Guides

- Front Panel - Spherical, Planar or Counterbore heads

- IP68 Front Panel - Spherical, Planar or Counterbore heads

- Flexible Light Guides

- IP68 Flexible Light Guides

- Front Panel - Square Heads

- IP54 Rated Sealing Disc

- Rear-mounted, Single

- Rear-mounted, Multiple

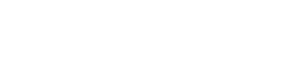

Front panel light guides / light pipes are the optimum solution when a design calls for a Light guides that is not physically attached to the PCB. They push-fit into a hole in the front panel and their light-inject face floats in close proximity to the SMD LED without actually making contact. Such an arrangement provides engineers with multiple design options.

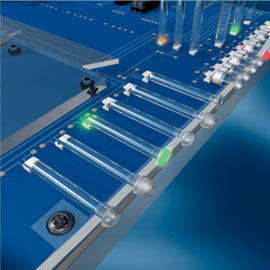

MENTOR‘s range of front panel light guides includes many variations with both 0° and 45° light injection faces to allow vertical and horizontal mounting as well as IP68-rated variants of almost the entire range. MENTOR‘s NEW rear-inserted ranges are unique and deliver optimum optical quality since the entire head is directly illuminated by the LED, which is not possible with industry-standard front-mounted versions.

UNLIMITED OPTIONS OF FRONT PANEL LIGHT GUIDES

MENTOR offers a wide assortment of front panel light guides and light pipes in both single and multiple versions. Designs are available in the classic diameters of 5.2mm, 5.0mm and 3.2mm plus miniaturised versions of 2.2mm diameter. IP68-rated versions are also available.

All of MENTOR’s front panel light guides are offered with a choice of head shape designs and in several standard lengths. Custom lengths are easily achievable and often incur low or even zero tooling costs with low MOQs.

FRONT PANEL LIGHT GUIDE DESIGN

Light guides form a key function in the human interface with a product, so their appearance and optical quality have a huge influence on aesthetics and overall perceptions. The options of square or round, spherical, planar or counterbore heads available in the MENTOR panel-mounted range provide design engineers with ultimate flexibility and allow them to design-in features to differentiate from their competition.

MENTOR light guides are visibly superior, premium-quality precision optics that will enhance the appearance of any electronic device.

FRONT PANEL LIGHT GUIDE INSTALLATION

MENTOR’s various front panel light guide designs provide a large degree of flexibility in mounting methods. Classic front-mounted panel light guides are the most common type and are available in a wide range of variants. These are offered with either straight or slanted light inject faces so both horizontal and vertical mounting is possible. The advantages of our new rear-mounted versions are detailed below.

DIFFERENTIATE YOUR PRODUCT WITH SQUARE FRONT PANEL LIGHT GUIDES!

SINGLE & MULTIPLE REAR-MOUNTED PANEL LIGHT GUIDES

By means of a joining strip, light guides from this rear-mounted series are combined to form a multiple light guide with a 5.08mm grid, thus making mounting an array a quick and cost-effective exercise. The flexibility of the joining strip allows compensation for pitch tolerances.

In addition to our standard rear-mounted light guides available from stock, custom variants are also available. In particular, the length of light guides can easily be customised with little or no tooling cost. The depth of the mounting flange can also be customised to accommodate unusual front-panel thicknesses. Customisation is often possible with little or no tooling cost.

CUSTOM FRONT PANEL LIGHT GUIDES

Despite the breadth of options in the standard MENTOR light guide offer, there will inevitably be instances when a custom light guide design is called for. Often, only a dimensional modification (normally Length A) is required and this can usually be delivered with little or no tooling cost and with a very modest MOQ. Other modifications such as different head shapes, dimensions or self-colouring are all usually possible. More information on the diverse possibilities of customised solutions is provided here.

- Quick Links

- Graphical Range Overview of Front Panel Light Guides

- Front Panel - Spherical, Planar or Counterbore heads

- IP68 Front Panel - Spherical, Planar or Counterbore heads

- Flexible Light Guides

- IP68 Flexible Light Guides

- Front Panel - Square Heads

- IP54 Rated Sealing Disc

- Rear-mounted, Single

- Rear-mounted, Multiple