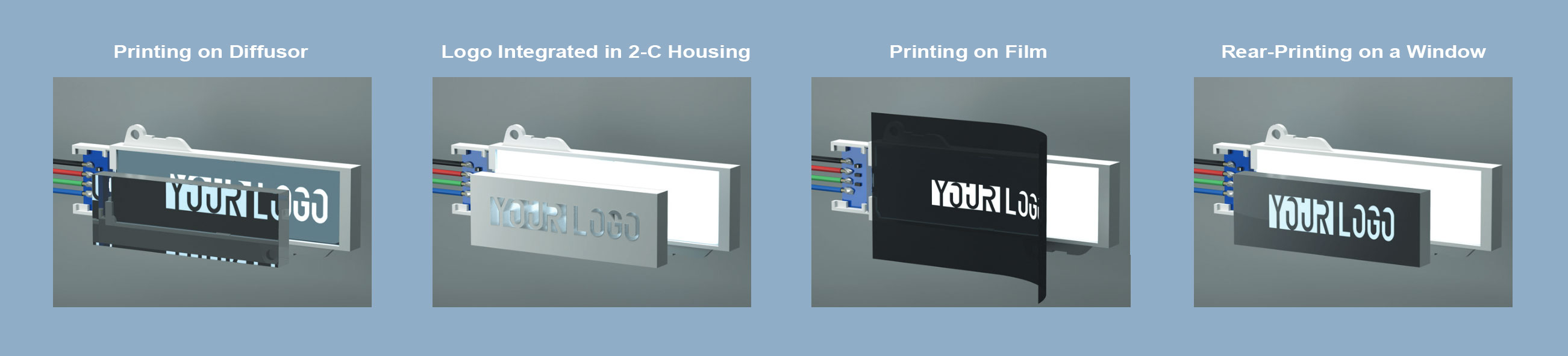

Option #1 - Printing Directly onto the Diffusor within the LED Module

With this method of printing, the desired logo, symbol or text is printed onto the integrated diffusor located within the module.

The printing allows light to shine through designated areas and the remaining print surface is impermeable, blocking out the light completely. A transparent window is required to protect the printing.

Option #2 - Logo created via 2-C Injection Moulding

This can be achieved either directly in the otherwise opaque face of a moulded enclosure, or by using a separate window which is inserted into the front panel of an enclosure.

The diffused area is backlit by the area lighting.

Option #3 - Printing onto a Film or Enclosure Overlay

Another way of adding logos, symbols and text to the MENTOR LED Module is to print directly onto a flexible film, foil or the enclosure’s overlay if fitted.

The film or foil is then used as a final element, which is attached to the front of end-product’s enclosure. The dark areas on the foil are completely impermeable to light.

Option #4 - Rear-Printing onto a Flush-Fitting Window

Customers will generally fit a flush-fitting transparent window to the aperture in their enclosure. Printing can be applied to the rear-face of this window.

Alternatively, a film can be printed and then applied to the rear of the window. With both approaches, the Area Lighting module produces the desired flush-surface lighting.