A Design Engineer’s GUIDE TO MENTOR'S LED LIGHT GUIDE SOLUTIONS

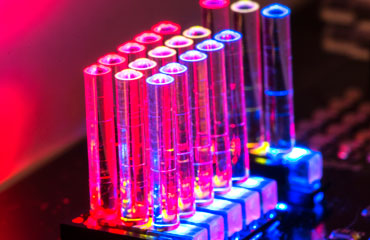

MENTOR LED Light Guides

MENTOR light guides, (also known as light pipes), are precision optics that precisely manage the light emitted from today's powerful LEDs. MENTOR are world-leading experts in the design and in-house manufacture of such components, and - as 1st-tier suppliers to major automotive and other OEMs - MENTOR is a preferred partner to deliver complete custom lighting / LED optics solutions.

MENTOR light guides offer electronic design engineers cost-efficient, space-saving and easy-to-install solutions with high ESD protection. MENTOR’s range of high quality range standard light guides to be installed in front panels or on printed circuit boards includes hundreds of articles, many of which are available from stock with small MOQs and short delivery times.

Their standard light guide range is amongst the most comprehensive in the world and includes over 450 part numbers, the majority of which are immediately available ex-stock. This comprehensive range allows even lower-volume projects to exploit MENTOR's LED competencies and dimensional variations are often possible with little or no tooling cost.

MENTOR’s new M-CUT 2-D custom light guides require no tooling investment and have low MOQs, thus opening a whole new creative world to Design Engineers with smaller volumes.

Find the ideal LED light guide for your application

This Microsite is designed to help Electronic Design Engineers in the UK easily identify the ideal light guide for their application. An overview of MENTOR's light guide expertise is provided here and, immediately below, the product range is divided into categories with direct links to detail pages and product overviews.

MENTOR LIGHT GUIDES PRODUCT RANGE

AREA LIGHTING FOR LOGOS, SYMBOLS AND TEXT - NEW, UNIQUE AND LOW MOQS!

MENTOR's new LED modules feature a flat panel design, making them ideal for displaying logos, symbols and text. The LED backlighting benefits from MENTOR's product lighting expertise, providing very even, truly homogeneous illumination. The module features a single RGB LED, offering an infinite range of backlight colours.

CIRCULAR / RING LIGHT GUIDES

NEW, UNIQUE, EX STOCK AND LOW MOQS!

Sophisticated lighting can add that “extra edge” to differentiate your product in the modern consumer world. MENTOR’s Circular “Ring” Light Guides provide an innovative, compact lighting solution with a thin, flat construction - just 4mm thick - that is suitable for many applications: illuminated switches, buttons, knobs, jacks etc.

NEXT GENERATION FRONT PANEL LED INDICATOR LIGHTS - EX STOCK, LOW MOQS!

These innovative front panel LED indicator lights by MENTOR are based on a single SMD LED, with a compact design and simple Push-fit assembly. Suitable for indoor or outdoor applications, waterproof, UV resistant and available in standard Ø3mm or Ø5mm versions as well as customisable with little or no tooling cost.

FRONT PANEL LIGHT GUIDES / PIPES

Front panel light guides / light pipes are the optimum solution when a design calls for a light guide that is not physically attached to the PCB. They push-fit into a hole in the front panel and their light-inject face floats in close proximity to the SMD LED without actually making contact. Ø5, Ø3 and miniature Ø2mm sizes, IP68-rated, square head and rear-mounted front panel light guides are all available.

General Description | Graphical Range Overview

- Links to the detail - Panel Light Guides

- Front Panel - Spherical, Planar or Counterbore heads

- IP68 Front Panel - Spherical, Planar or Counterbore heads

- Flexible Light Guides

- IP68 Flexible Light Guides

- IP68 Light Guide and Front Panel LED Light Overview

- IP68 Front Panel LED Lights

- Front Panel - Square Heads

- IP54 Rated Sealing Disc

- Rear-mounted, Single

- Rear-mounted, Multiple

M-CUT 2-D CUSTOM LIGHT GUIDES / PIPES

The shape and dimensions of these 2D light guide systems can be customer-specified with no tooling cost and an MOQ of just 300pcs!! MENTOR will advise on the type and position of LEDs and validate optical performance using specialist software.

M-CUT light guides are available in three customisable types: area, bargraph and solid strip.

- Links to the detail - Custom Light Guides

- Custom Area Light Guides. (No tooling, 300pcs MOQ)

- Custom Bargraph Light Guides. (No tooling, 300pcs MOQ)

- Custom Solid Strip Light Guide. No tooling, 300pcs MOQ)

FLEXIBLE LIGHT GUIDES / PIPES

Flexible light guide systems from MENTOR offer an elegant and cost-efficient solution for many opto-electronic design challenges - not least for a minor design change during a mid-cycle face-lift. The most popular versions are designed for use with SMD TOPLEDs, although THT versions are also offered.

General Description | Graphical Range Overview

- Links to the detail - Flexible Light Guides

- Ø3mm, Ø6mm head, for SMD LEDs

- Ø2mm, Ø5mm head, for SMD LEDs

- Switch, (3-LED, tri-chromatic), 2000μm or 1000μm

- Switch, THT LED, 2000μm or 1000μm

- Multi-element flex light guide for SMD LEDs

- IP68 Flexible Light Guide System

- IP68 Light Guide and Front Panel LED Light Overview

- IP68 Front Panel LED Lights

- IP68 Rigid Front Panel Light Guides

- Angle holder for flex light guides, Ø2mm and Ø3mm

- Length-extender for flex light guides 1000μm and 2000μm

- Flex Light Guide System 3,000μm

HORIZONTAL LIGHT GUIDES / PIPES

Horizontal PCB-mounted light guides from MENTOR are used in applications that call for light to be emitted from a panel that is positioned at right angles to the circuit board. MENTOR offers both classic Ø3mm element versions for the 5.08mm grid and miniaturised Ø2mm versions for the 2.54mm grid, as well as hybrid combinations of the two types. Round, square and rectangular element versions are all available. Despite the close proximity of tiny elements, clever design coupled with precision manufacture ensures that there is no light bleed, even when different colours are adjacent.

General Description | Graphical Range Overview

- Links to the detail - Horizontal Light Guides

- Horizontal, single element, Ø3mm

- Horizontal, 1 row, 1-10 columns, Ø3mm

- 1-row, 1-10-columns, miniature 2.54 grid, Ø2mm

- 2-Row, 1-column, Ø3mm

- 2-row, multi-column, Ø3mm

- 2-row, multi-column, miniature 2.54mm grid, Ø2mm

- 3-row, single-column, Ø3mm

- 3-row, multi-column, miniature 2.54mm, Ø2mm grid

- 4-row, single-column, Ø3mm

- 4-row, multi-column, Ø3mm

- 4-row, single and multiple columns, 5.08mm grid, Ø2mm

- 4-row, multi-column, miniature 2.54mm grid, Ø2mm

- 1-row, multi-column, miniature 2.54mm grid, 1.4mm square

- 3-row, multi-column, miniature 2.54m grid, 1.4mm square

- 1-row, 1-10 columns, rectangular, 2mm x 5mm

- 1-row, multi-column, miniature 2.54mm grid, 3mm x 2mm

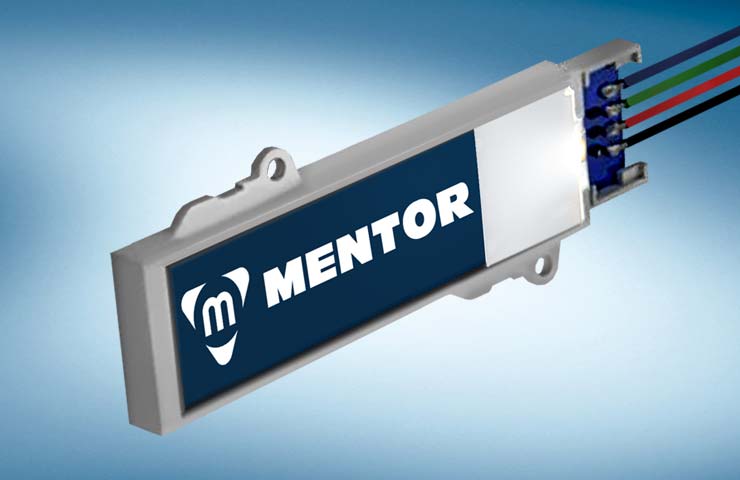

VERTICAL LIGHT GUIDES / PIPES

Vertical PCB-mounted light guides from MENTOR are used in applications that call for light to be emitted from a panel positioned parallel to the circuit board. MENTOR offers these upright light guides in both classic Ø3mm element versions for the 5.08mm grid and miniaturised Ø2mm versions for the 2.54mm grid, as well as hybrid combinations of the two types. Both round and rectangular element versions are available. As with MENTOR's horizontal light guides, clever design and precision manufacture ensure that there is no light bleed, even when different colours are adjacent.

General Description | Graphical Range Overview

- Links to the detail - Vertical Light Guides

- Single element, 2-part component, Ø3mm & Ø5mm

- Single element, Ø3mm

- Single element, triple LED switch, tri-chromatic, Ø3mm

- 1-row, Multi-column, Ø3mm

- 1-row, multi-column, miniature 2.54mm grid, Ø2mm

- 2-row, multi-column, miniature 2.54mm grid, Ø2mm

- 3-row, multi-column, miniature 2.54mm grid, Ø2mm

- 4-row, multi-column, miniature 2.54mm grid, Ø2mm

- 4-row, multi-column, 5.08mm grid, Ø2mm

- Single element, rectangular, 2mm x 5mm

- 1-row, multi-column, rectangular, 2mm x 5mm, bargraph

- 1-row, multi-column, mini 2.54mm grid, rect, 2 x 5mm

- 1-row, multi-column, mini 5.08mm PCB, 2.54 elem. grids, rect. 2 x 3mm

CUSTOM LED LIGHT GUIDE DESIGN

MENTOR has unique competencies in custom light pipe design and manufacture. Few companies globally can equal its combination of innovative, engineering-led and precisely-simulated design supported by “boringly efficient” manufacturing performance. Most of MENTOR’s 500+ standard (ex-stock & low MOQs) light guides can be modified in terms of dimension and fixings with little or no tooling cost. In addition, MENTOR’s highly-qualified lighting engineers can produce cutting-edge, customer-specific product lighting solutions. Please contact Multitron so we can guide you towards a solution to your lighting challenge.